Electrical Rating

Model WDS

Single Phase |

Volts |

240V |

| Phase ⁄ Hz |

1 ph ⁄ 50 Hz |

| Amps |

20 Amps |

Internal circuit breakers

Single Phase |

Heater power supply pcb |

1 pole 20A 240Vac |

| Control power supply pcb |

1 pole 10A 240Vac |

Heating Elements

Single Phase |

Steam Generator |

4500W 240V 3 x 6.25A Star |

| Water tank |

4500W 240V 3 x 6.25A Star |

| |

Electrical Rating

Model WDS

Three Phase |

Volts |

415V |

| Phase ⁄ Hz |

3 ph ⁄ 50 Hz |

| Amps |

20 Amps |

Internal circuit breakers

Three Phase |

Heater power supply pcb |

3 pole 20A 415Vac |

| Control power supply pcb |

1 pole 10A 240Vac |

Heating Elements

Three Phase |

Steam Generator |

4500W 240V 3 x 6.25A Star |

| Water tank |

7200W 240V 3 x 10A Star |

ContactorsHeating Elements

Three Phase unit |

Steam heating element |

3 pole 7.5kw |

| W ⁄ tank heating element |

3 pole 7.5kw |

| ELECTRICAL Common components |

| Element over temperature cut–out |

Steam Generator |

Capillary bulb thermal cut–out

Manual reset 115°C 25A |

| Water tank |

Capillary bulb thermal cut–out

Manual reset 100°C 25A |

| Fuse: Transformer |

Cylinder type 5 x 20mm |

T 5A H 250Vac Time Delay |

| Processor module battery |

Coin Cell |

CR2032 Lithium 3 Volts |

| |

|

|

| |

Relative Humidity |

+30% to 70% |

| PCB HARDWARE |

| PCB (Printed Circuit Boards) |

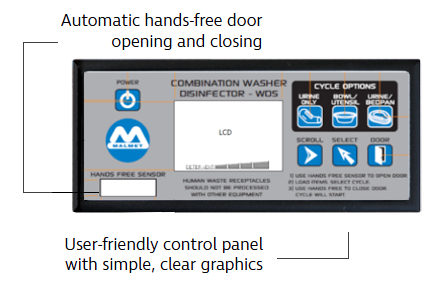

Display LCD |

D134411 |

| Heating switch module |

D132213 |

| Control module |

D134412 |

| Processor module |

D133447 |

| Conductivity sensor |

D134418 |

| Logger data download |

Via |

USB port |

| Software loading |

Via |

USB port |

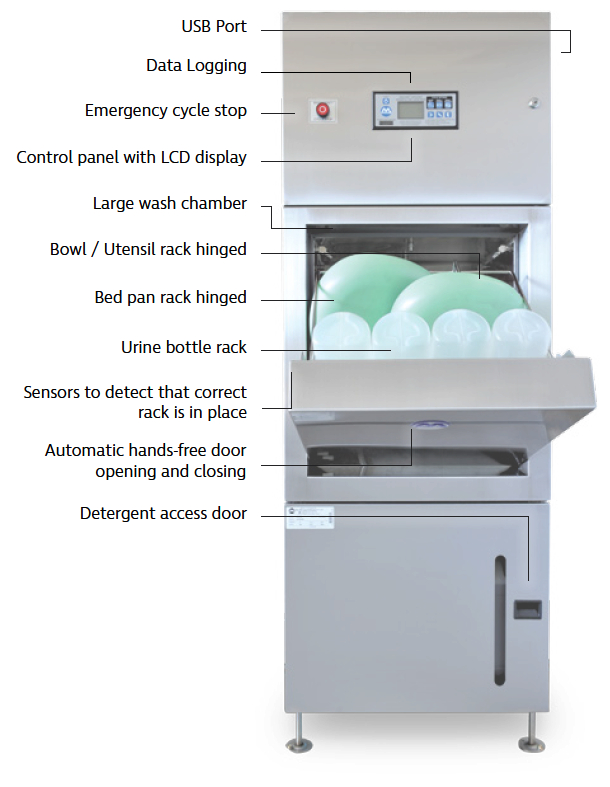

| LOADING CAPACITY |

| Wash Chamber Capacity |

Bedpans ⁄ Urine Bottles |

4 x Urinal Bottles

2 x STD Bed Pan & Lid

2 x Small slipper pans & Lid

2 x Large Slipper Pan & Lid |

| Urine Bottles only |

4 x Urine Bottles |

| Bowls ⁄ Utensils |

2 x Large Bowls

3 x Medium Bowls

Smaller Bowls and Kidney

Dishes in Accessory Basket

6 x Large Kidney Dishes

6 x Medium Kidney Dishes |

| WASH SYSTEM |

| Nozzles and Sprays |

Flush Nozzles |

2 x Rotary Nylon |

| Tip Sprays |

2 x WL1/2 120° 1/8 bsp ss |

| Top Sprays |

4 x WL1/4 90° 1/8 bsp ss |

| Bottom Sprays |

4 x WL1/2 60° 1/8 bsp ss |

| Urine Bottle Sprays |

4 x WL1/4 90° 1/8 bsp ss |

| Cool Down Sprays |

2 x LW1 120° 1/4 bsp ss |

| Wash Pump |

Horizontal Multistage |

750W 240V 1ph 4.6A

116.7L ⁄ Mins

s ⁄ s impeller and housing |

| |

| Detergent |

Malmet specific (5Lt) |

Detergent Concentrate Caustic Alkaline

(ARTGC Class 1) |

| Detergent Pump |

Self priming peristaltic

Chemical feed pump |

72 rpm 240V 50Hz |

| PLUMBING |

Soil line Connection

Complies to AS 2887 & AS ⁄ NZS 3500.2:2003 |

Type |

‘S’ or ‘P’ Trap (6mm PE) 80° |

| Size |

100mm ID |

Backflow Prevention

AS 2845.2 – 1996 |

Air Gap (RAG) |

Water storage tank |

| Cold water inlet Supply |

Temp – Pressure (Flow) |

15 – 25°C @ 100 – 350kpa |

| Solenoid Valve 1 in 2 out |

240V – GB¾ male, WRAS Certified |

| Hot Water inlet supply |

Temp – Pressure (Flow) |

55 – 60°C @ 100 – 350kpa |

| Solenoid Valve 1 in 2 out |

240V – GB¾ male, WRAS Certified |

| Minimum water flow @ 100 Kpa |

|

9.377 L ⁄ min |

| Hose – valve to Water Tank |

Stainless Steel Braided |

10mm, WRAS Certified |

| Hoses – Mains Water Supply to Inlet Valve |

Stainless Steel Braided Assembly H ⁄ C Water |

G¾ Hex Nut Each End 1.5M x 10mm, Cert to AS ⁄ NZS 3499-2006 |

| CONSTRUCTION MATERIALS |

| Materials |

Frame |

25 x 25 x 1.6 tube SS |

| Wash chamber |

316 SS grade 4 |

| Door |

316 SS grade 4 |

| External panels |

304 SS grade 4 |

| Water tank |

316 SS grade 2B |

| Steam generator |

316 SS grade 2B |

| Fasteners |

304 ⁄ 316 SS |

| Thermal insulation chamber and water tank |

TBA |

| ENVIROMENTAL |

| Environment conditions Transport and Storage |

Fragile, Keep away from rain |

Do not stack |

| Temperature |

-5°C to +50°C |

Environment Operating

Conditions |

Temperature |

+10°C to +25°C |

| Relative Humidity |

+30% to 75% |

| Shipping Details |

Height x Width x Depth (mm) |

1770 x 800 x 750 |

| Weight = Packaging + Det |

163 Kg |

Return to top of page

Return to top of page

Email for more information.

Email for more information.